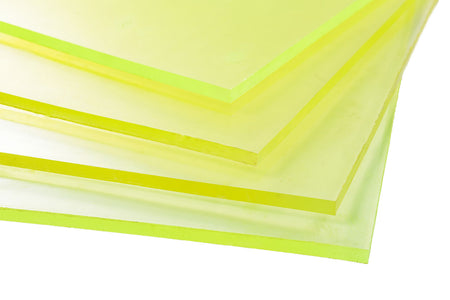

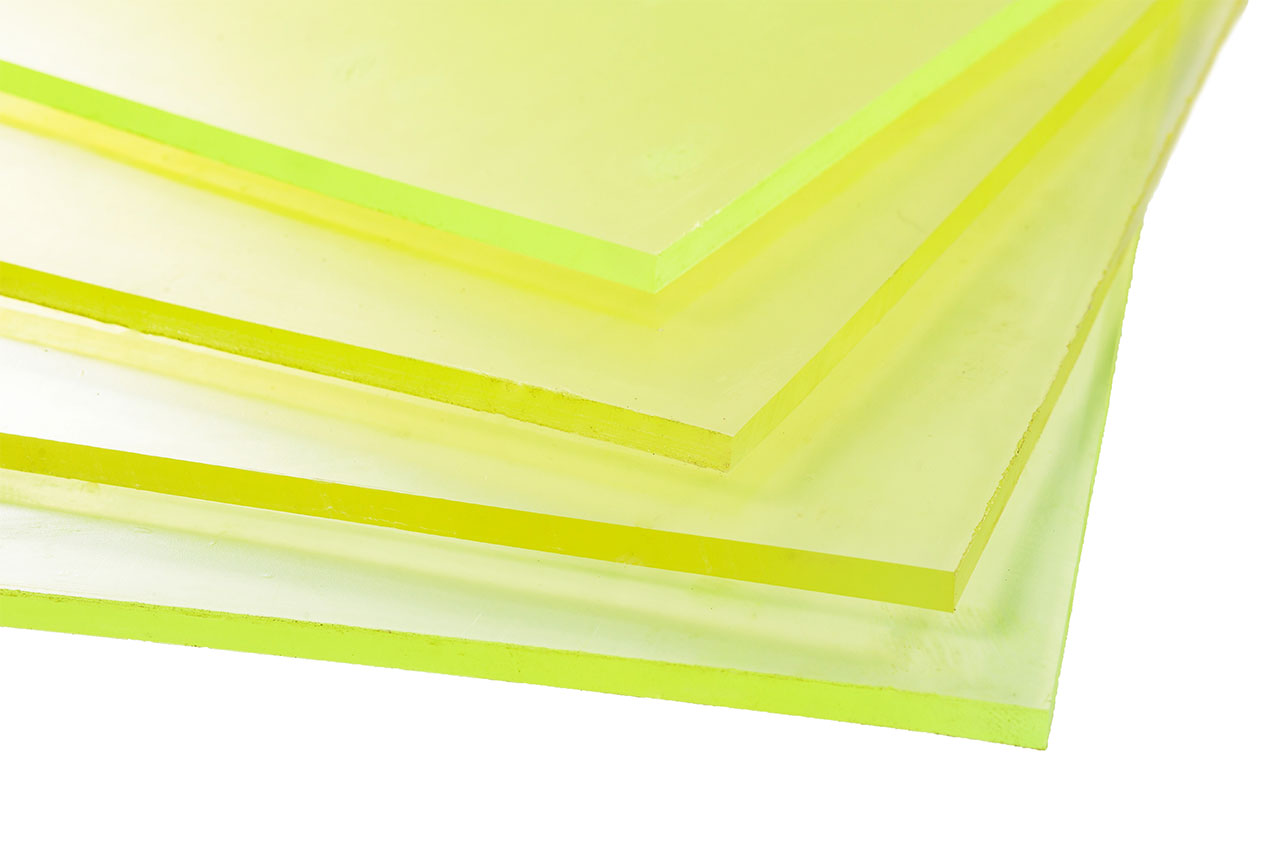

Polyurethane Sheet

Couldn't load pickup availability

Stefsotra Polyurethane Sheets – Durable, High-Performance Material for Industrial Applications

Stefsotra Polyurethane Sheets are high-quality, versatile materials used in a wide range of industrial and manufacturing applications. With a hardness of 80 Shore A, these polyurethane sheets offer exceptional abrasion resistance, strength, and flexibility. Available in multiple thicknesses (3 mm, 5 mm, 7 mm, 10 mm, 15 mm) and a standard sheet size of 500 x 500 mm, these sheets are ideal for use in bunkers, hoppers, silos, and other equipment in technological lines.

Polyurethane has three times the wear resistance of rubber and is 2.5 times stronger in tensile strength than rubber, making it a superior alternative to rubber, plastic, and rubberized materials. Additionally, it is resistant to organic oils, alcohols, gasoline, and other petroleum-based substances, providing long-lasting protection in even the harshest environments.

Key Features:

- Available Thicknesses: 3 mm, 5 mm, 7 mm, 10 mm, 15 mm for versatile use across different applications.

- Hardness: 80 Shore A, providing a balance of flexibility and durability for industrial uses.

- Size: 500 x 500 mm sheets, easy to handle and install.

- High Wear Resistance: Polyurethane's wear resistance is three times greater than rubber, making it ideal for high-impact applications.

- Increased Strength: Tensile strength of polyurethane is 2.5 times greater than that of rubber, ensuring durability and reliability in demanding environments.

- Chemical Resistance: Resistant to oils, alcohols, gasoline, UV radiation, ozone, moisture, and other environmental factors, ensuring long-term performance.

- Mold and Microbe Resistance: Helps prevent the growth of mold and other microorganisms, providing cleaner and safer operational environments.

- Versatile Applications: Used for lining bunkers, hoppers, silos, vibration-resistant floors, seals, rollers, wheels, and other industrial components.

Polyurethane sheets are often used in the production of seals, bearing surfaces for rollers and wheels, and vibration-resistant flooring in industrial and manufacturing environments. Their ability to withstand extreme conditions, including abrasion, moisture, and chemical exposure, makes them a highly effective replacement for rubber, plastics, and other materials.